| Location: | Murimoos, Switzerland |

|---|---|

| Biomass: | Green waste, manure (horse, poultry, cattle) |

| Quantity: | ≤ 4.300 t/a |

| Biogas: | 380.000 Nm3/a |

| Performance: | 97 kW el. Ø |

BIOGAS PLANT & COMPOSTING SITE

Murimoos, Switzerland

For over three decades, “Murimoos werken und wohnen” has been producing compost on its own site from solid manure and green waste from the surrounding communities. Since 2018, the biomass has been used to generate energy in a biogas plant before being composted.

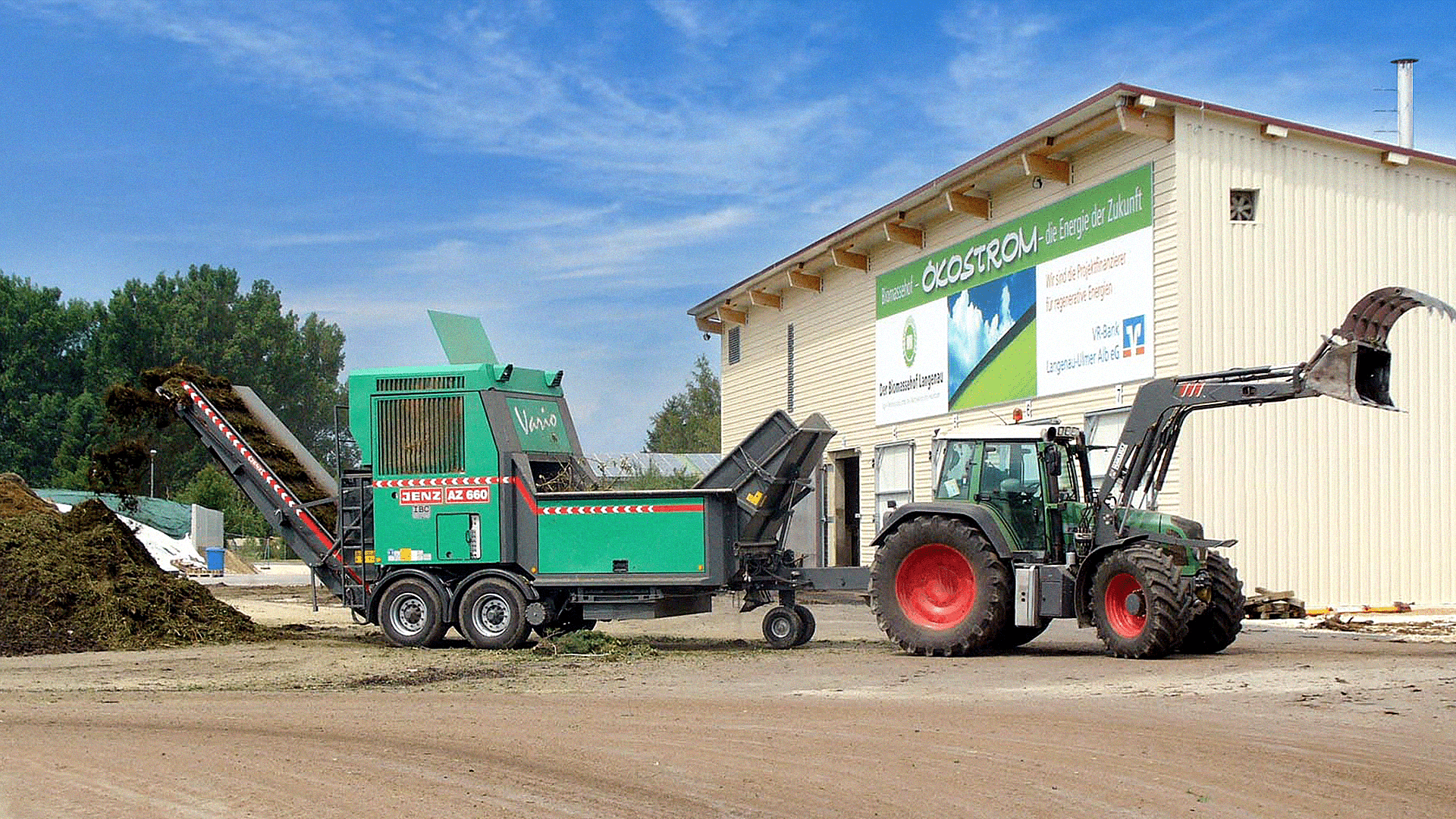

Turning green waste into compost is an ecologically valuable and sustainable process. Garden waste, kitchen scraps, branches, hedge cuttings and animal manure are transformed into high-quality compost.

Generating electricity from biogas

In line with the circular economy, the biomass is used to generate energy before composting. The biogas produced in the biogas plant is used to generate electricity in combined heat and power plants, with a significant amount of heat being generated at the same time. This means that numerous households can be supplied with electricity. The heat generated is used to regulate the temperature of the anaerobic digestion plant to 52 °C (thermophilic conditions) and to heat neighboring buildings. Fermentation, unlike composting, takes place through the microbial decomposition of organic substances in the absence of air (anaerobic). This produces a combustible gas mixture of approx. 55% methane (CH4) and approx. 45% carbon dioxide (CO₂) in warm and humid conditions. A full bio-bin with a capacity of 120 liters has the potential to generate an amount of energy equivalent to 3–4 liters of heating oil.

Dry fermentation biogas plant

In Murimoos, dry fermentation is used to produce biogas.

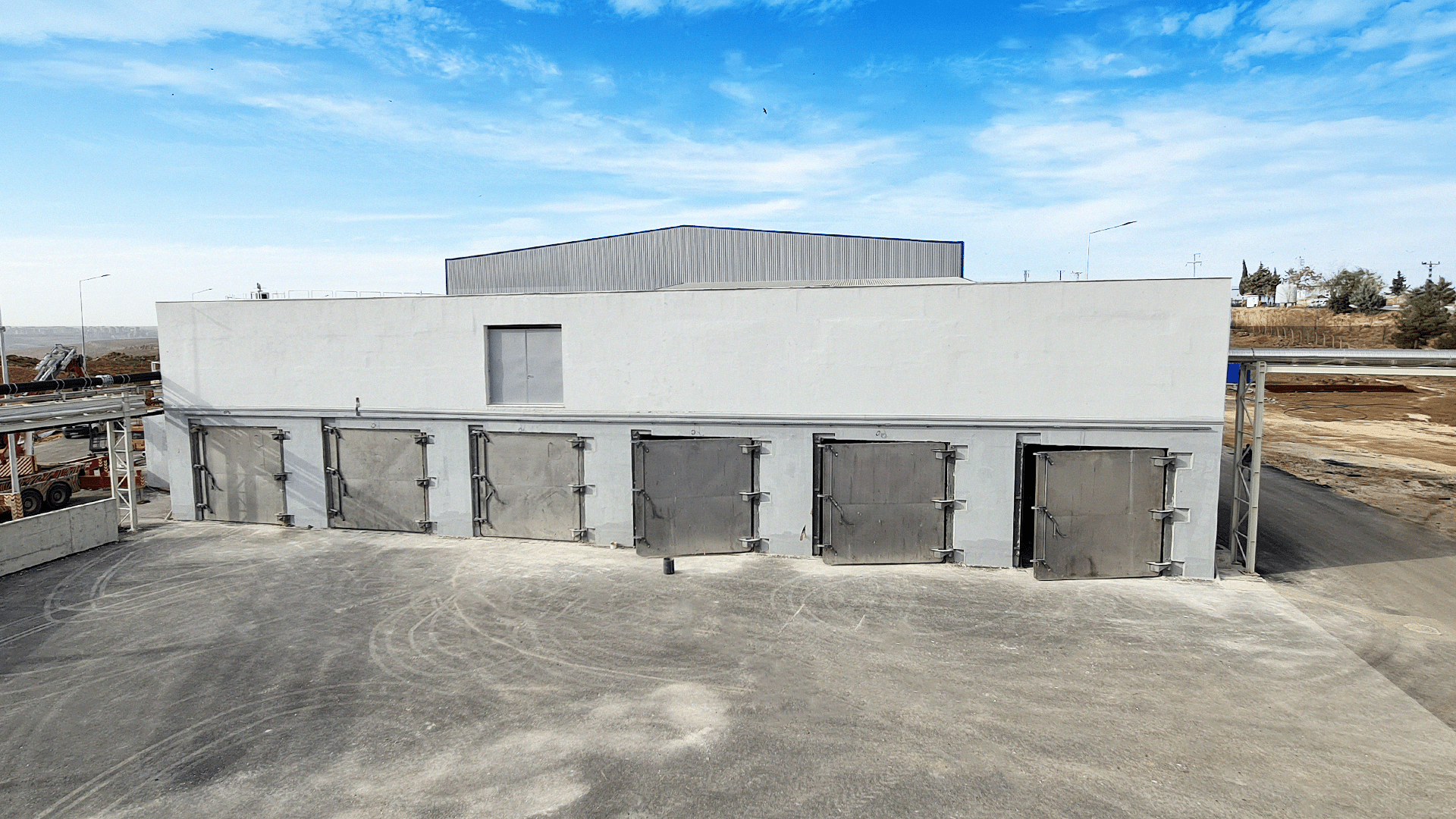

A wheel loader layers the substrate into the next free garage fermenter, which is sealed gas-tight by a gate-like system with an inflatable seal. The process water percolate then circulates in the system, irrigates the biomass and thus starts the decomposition into biogas. This percolate cycle ensures the even distribution of microorganisms, moisture, heat, and nutrients in the biomass pile. The organic matter is not moved during the 21-day retention period, which is why no complex pumping and stirring technology is required. The fermenters are changed once or twice a week, consisting of emptying and refilling, in order to guarantee consistent gas production. Pre-treatment of the substrates, such as shredding, is usually not necessary.