| Location: | Tägerwilen, Switzerland |

|---|---|

| Biomass: | (80%) green waste, (20%) livestock manure |

| Quantity: | ≤ 14.000 t/a |

| Biogas: | 970,000 Nm3/a |

| Performance: | Ø 940 kg Biomethan per day |

BIOGAS PLANT & COMPOSTING SITE

Tägerwilen, Switzerland

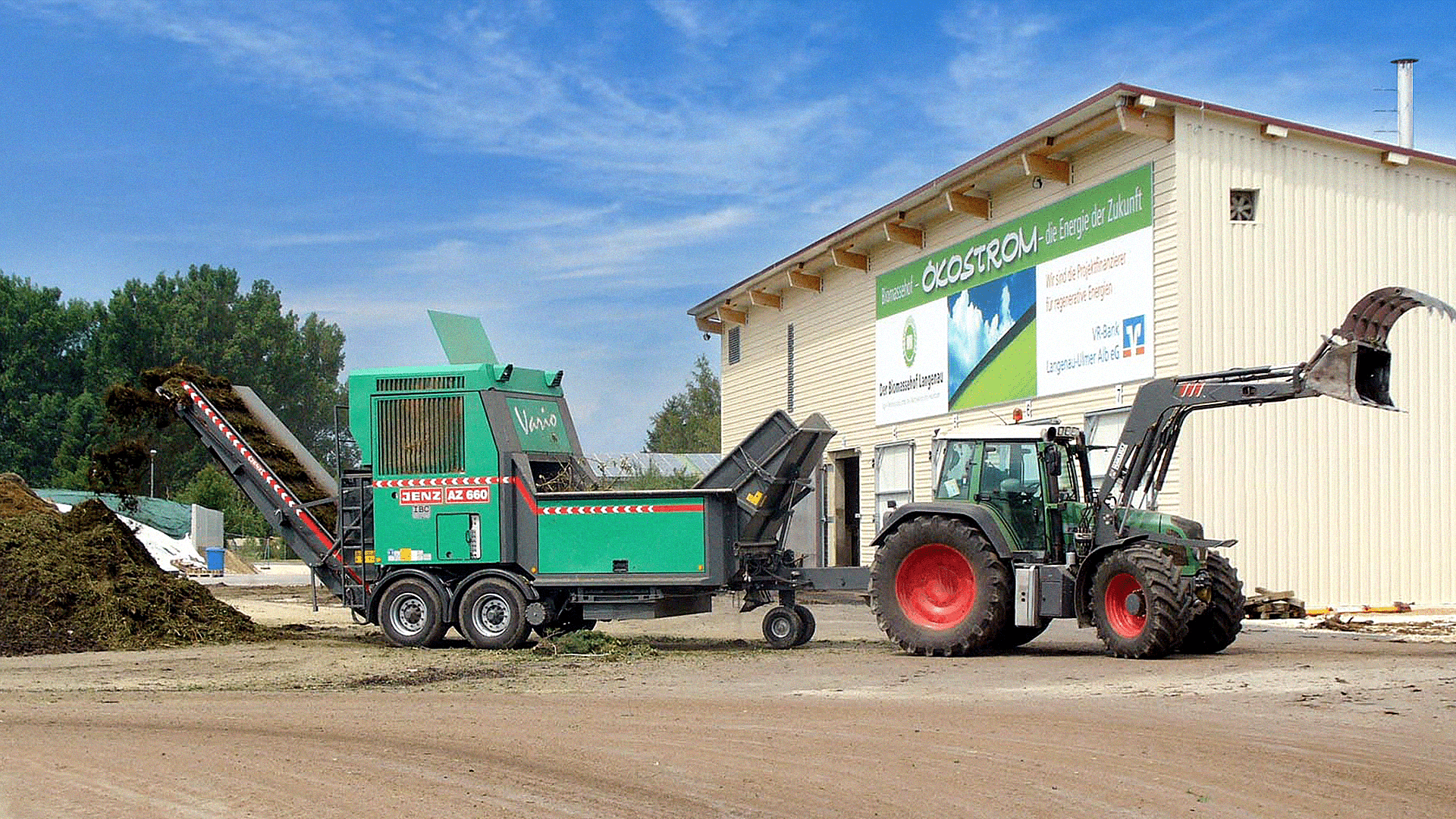

In the canton of Thurgau, around 49,000 tons of green waste are delivered to collection points every year. These pass the waste on to one of almost 40 processing plants, mostly field-side composting plants. Only around a fifth of the plants are biogas plants, which could utilize the green waste for energy, but are not suitable in terms of the type of plant. According to the biomass concept of the Canton of Thurgau from 2014, more biomass should be made available for fermentation in biogas plants and utilized locally for energy production.

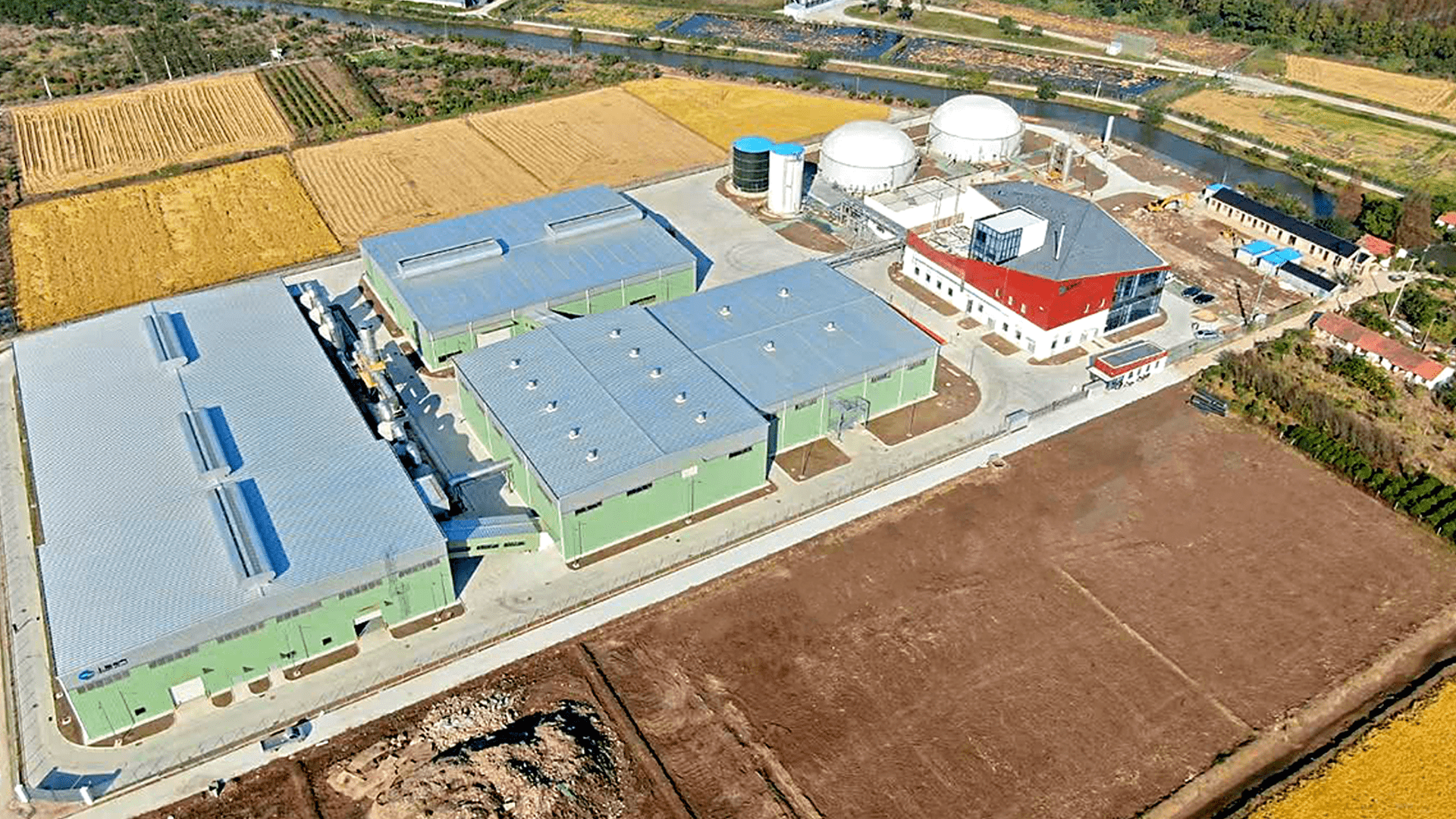

In the green waste fermentation plant in Tägerwilen, right next to the composting site, the delivered green waste is first used for energy and then for material recycling. The biomethane produced is fed into Kreuzlingen’s natural gas network.

The construction of the biogas plant in Tägerwilen is an absolute novelty and flagship project in Thurgau. For the first time, green waste from the municipal collection, landscaping material, garden waste, scraps, and waste from agriculture and animal husbandry are being recycled here in accordance with the cantonal biomass concept. The existing composting plant was integrated into the plant concept. The required green waste is delivered and processed directly from Kreuzlingen, Tägerwilen, Bottighofen and the surrounding area over short distances. And, incidentally, there are interesting possibilities for the production of soil-improving, humus-forming compost for hobby and landscape gardeners.

With the new biogas plant for solid matter fermentation in Tägerwilen, biogas produced from local green waste is fed into the gas network of Technische Betriebe Kreuzlingen – and the new plant is also making Thurgau biogas history! It is the first of its kind in Thurgau to utilize both green waste and biogenic residues, including waste containing straw, in accordance with the cantonal biomass concept – and has an integrated composting plant.

Dry fermentation process

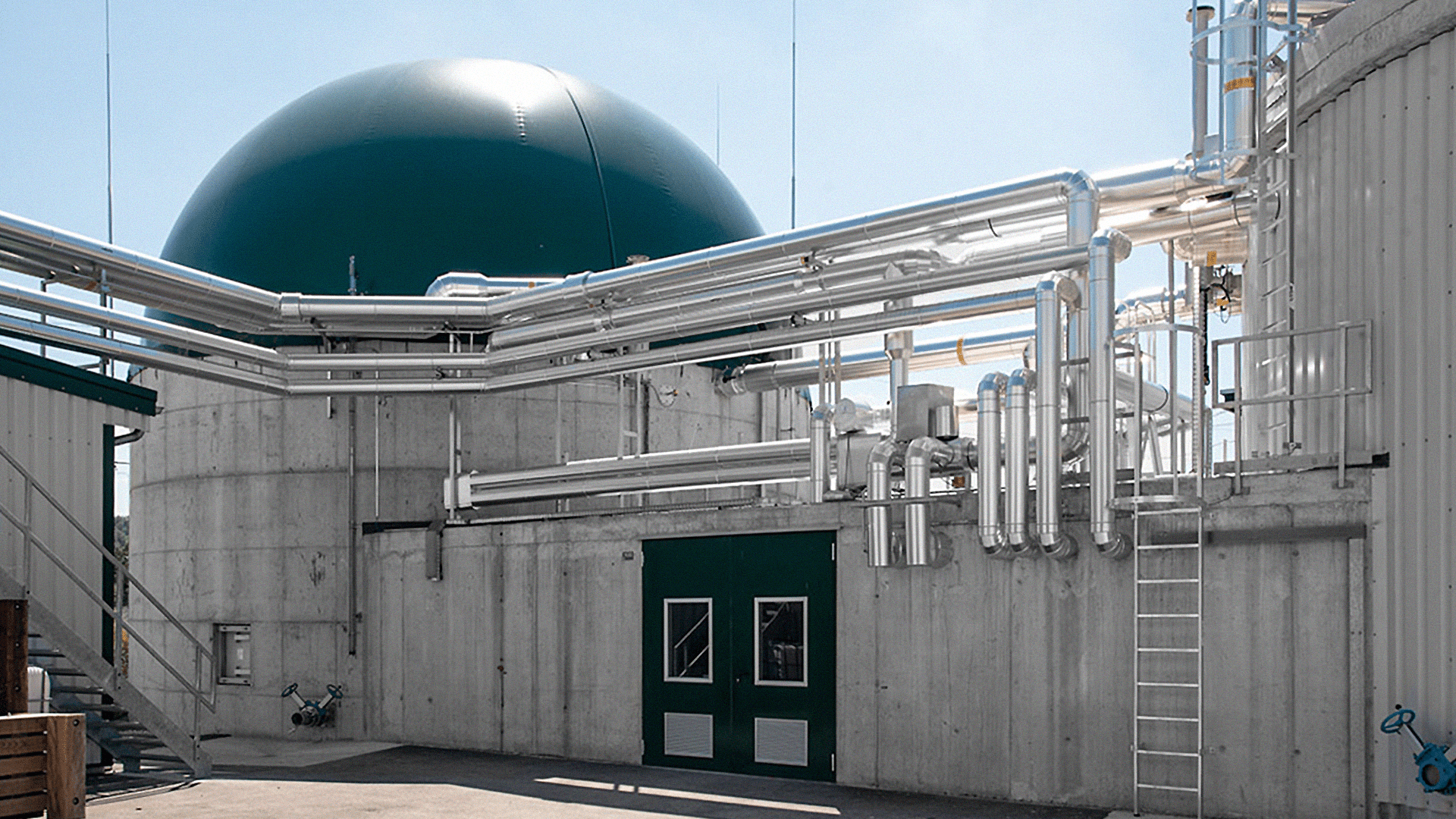

Dry fermentation is used to produce biogas in Tägerwilen.

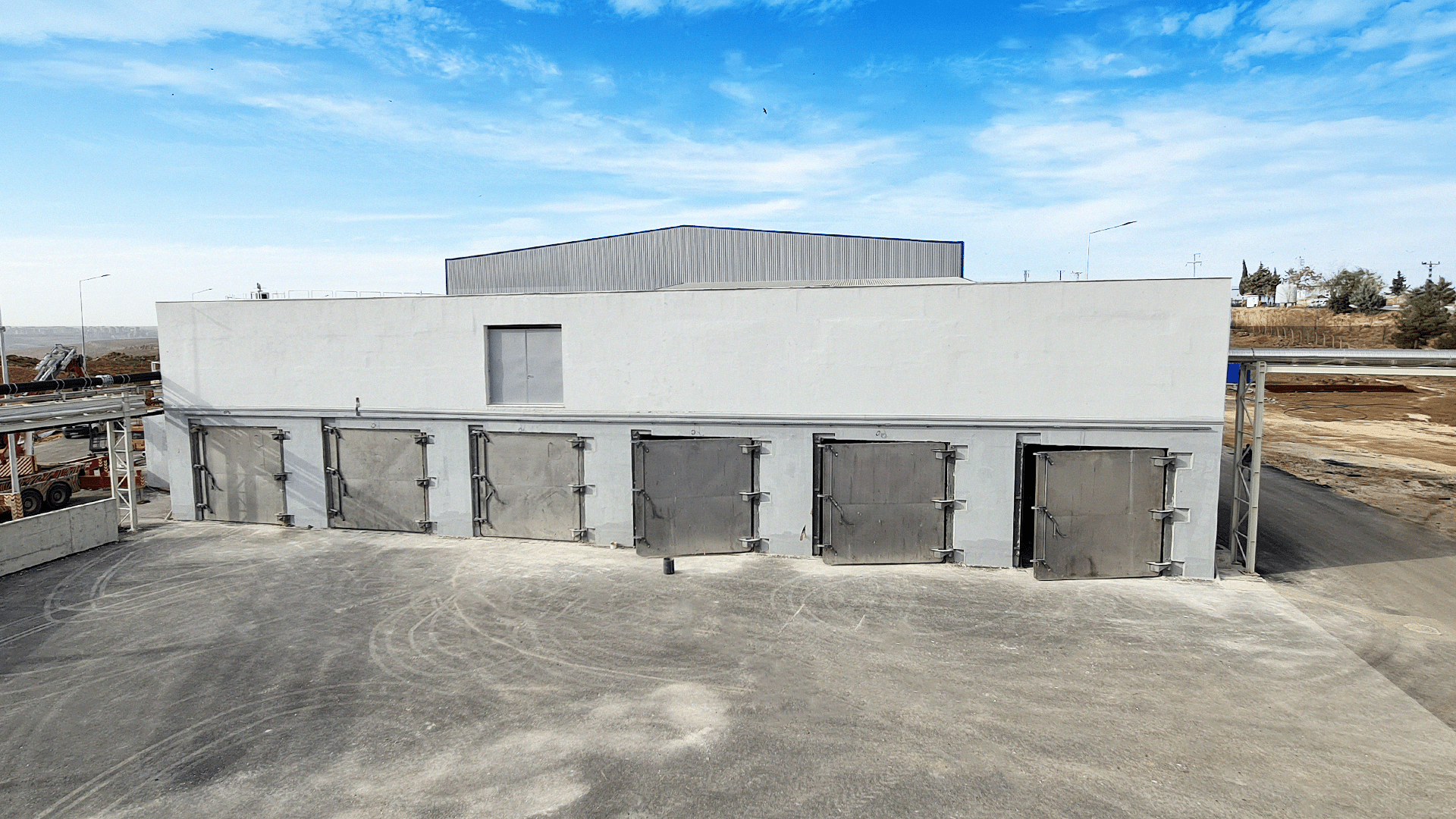

A wheel loader stacks the substrate in the next available garage fermenter. This is sealed gas-tight by a door with an inflatable seal. The process liquid percolate is then fed into the circuit, the biomass is irrigated and thus the decomposition process of the stackable biomass in the fermenter boxes to biogas is started and maintained. This percolate cycle ensures that relevant microorganisms, moisture, heat and essential nutrients are evenly distributed in the biomass pile. The organic material is not moved during the entire retention time of 21 days. Therefore, solid matter fermentation does not require any complex and susceptible pumping and stirring technology. One to two fermenter changes are carried out per week, consisting of emptying and refilling. By staggering the filling of the fermenter boxes, a largely constant gas production can be ensured. Pre-treatment, such as shredding the substrates, is generally not necessary.

The biogas produced is temporarily stored in a gas storage tank. The raw biogas is processed in a biogas upgrading plant to produce biomethane of natural gas quality (>96% methane) and is then fed directly into the gas pipeline network of Technische Betriebe Kreuzlingen (TBK). In this way, biogas can be made available to all TBK customers who also use natural gas. Since January 2020, TBK gas has already contained a fixed biogas share of 10% in the basic supply. This means that 10% of gas consumption is already renewable. In the future, purchasers, and customers will be able to adjust the proportion of biogas individually, to 20%, 40% or 100% for each gas connection.