HIGH SOLIDS ANAEROBIC DIGESTION SYSTEMS

FOR MUNICIPAL, INDUSTRIAL AND AGRICULTURAL MARKETS

For composters, disposers, municipalities and cities

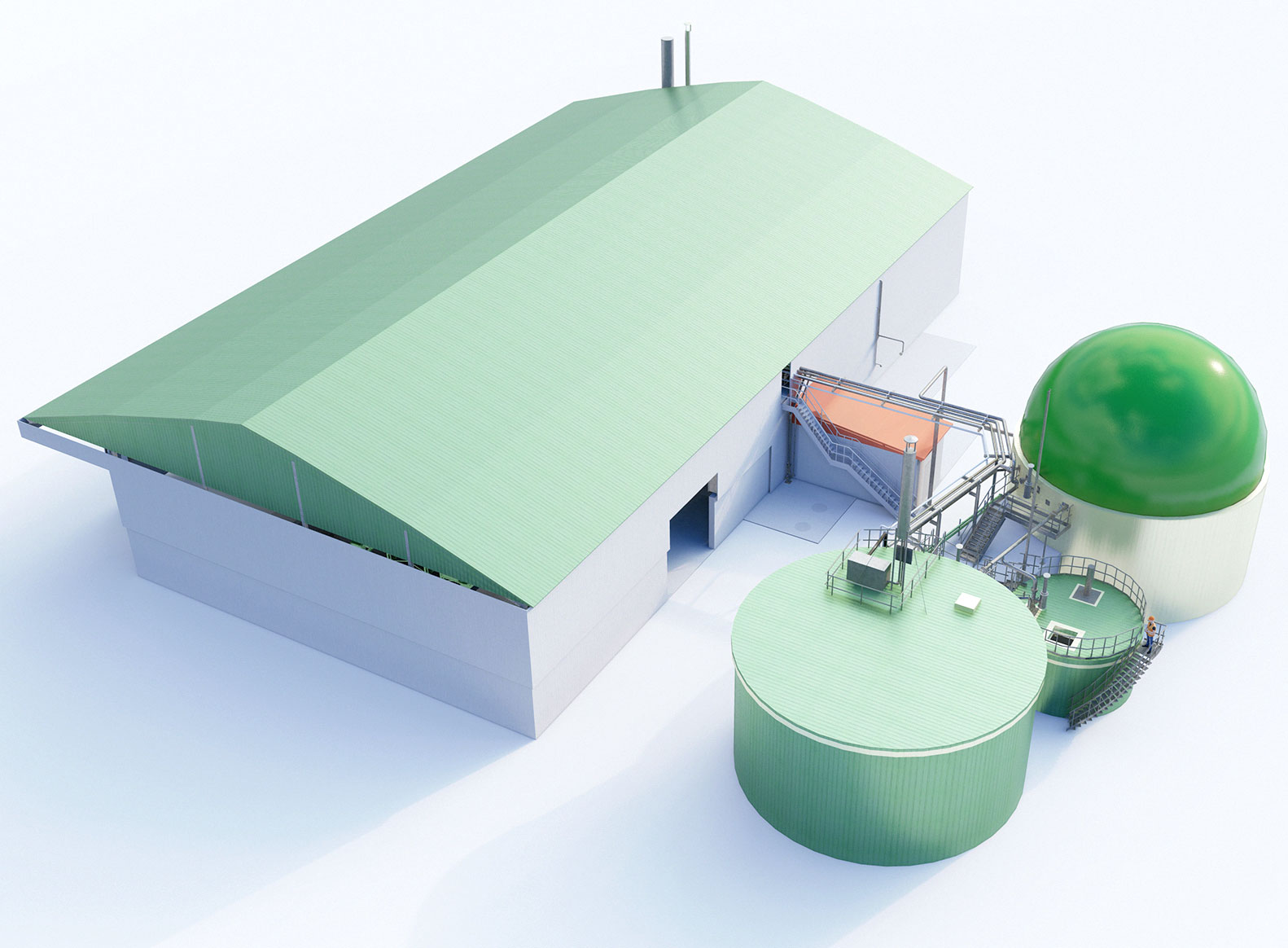

RSD-E Organic Waste Facility

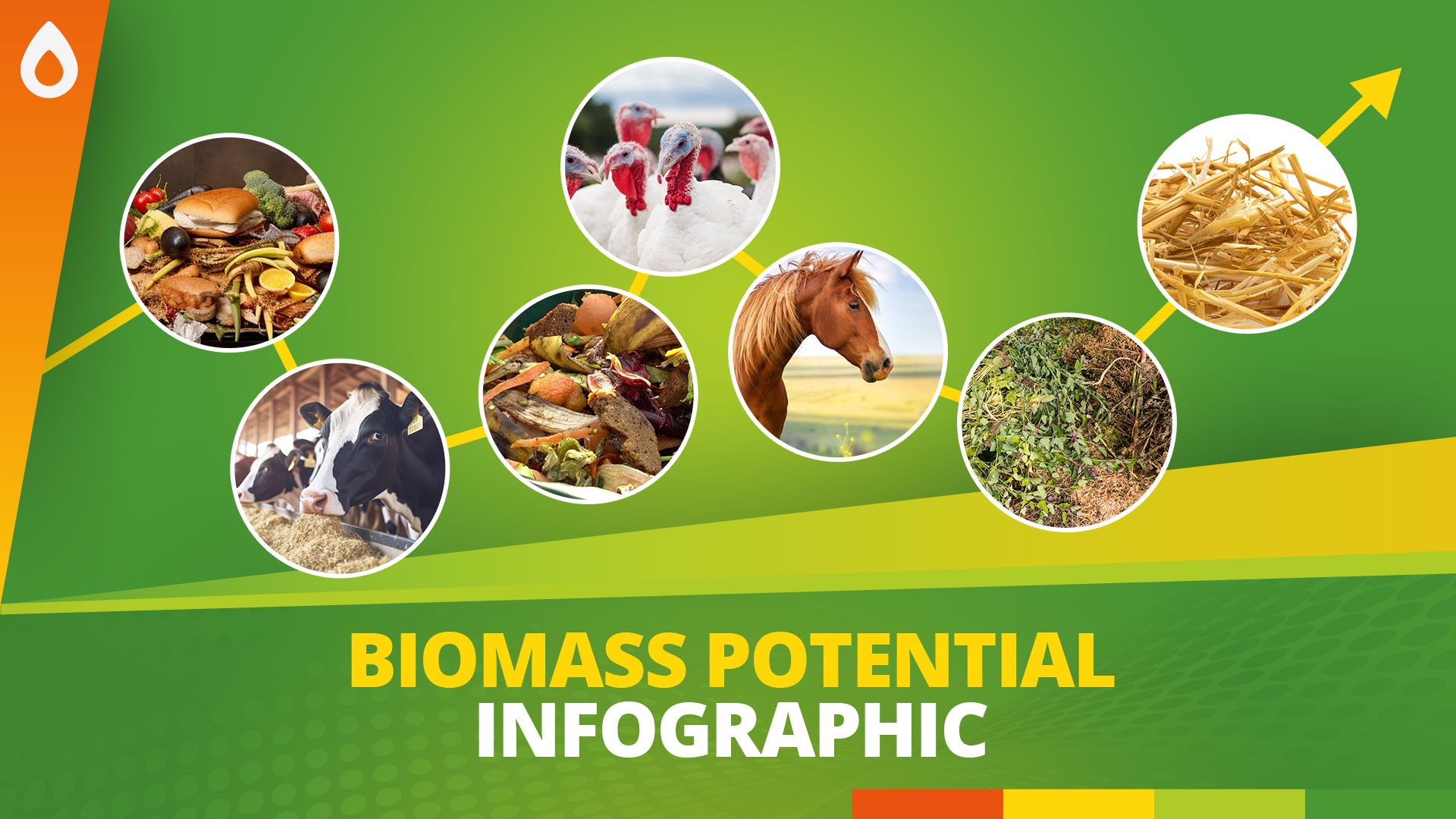

The adaptable architecture of the RSD-E biogas plant for solid-state fermentation ensures peak efficiency and economic viability, while considering particular local needs. It represents innovative decentralized energy generation (electricity, heat, biomethane – CNG, LNG) from a diverse array of stackable substrates, including solid manure, straw, biowaste, green cut waste, and substantial amounts of harvest and food residuals, suitable for municipal, industrial, and agricultural applications.

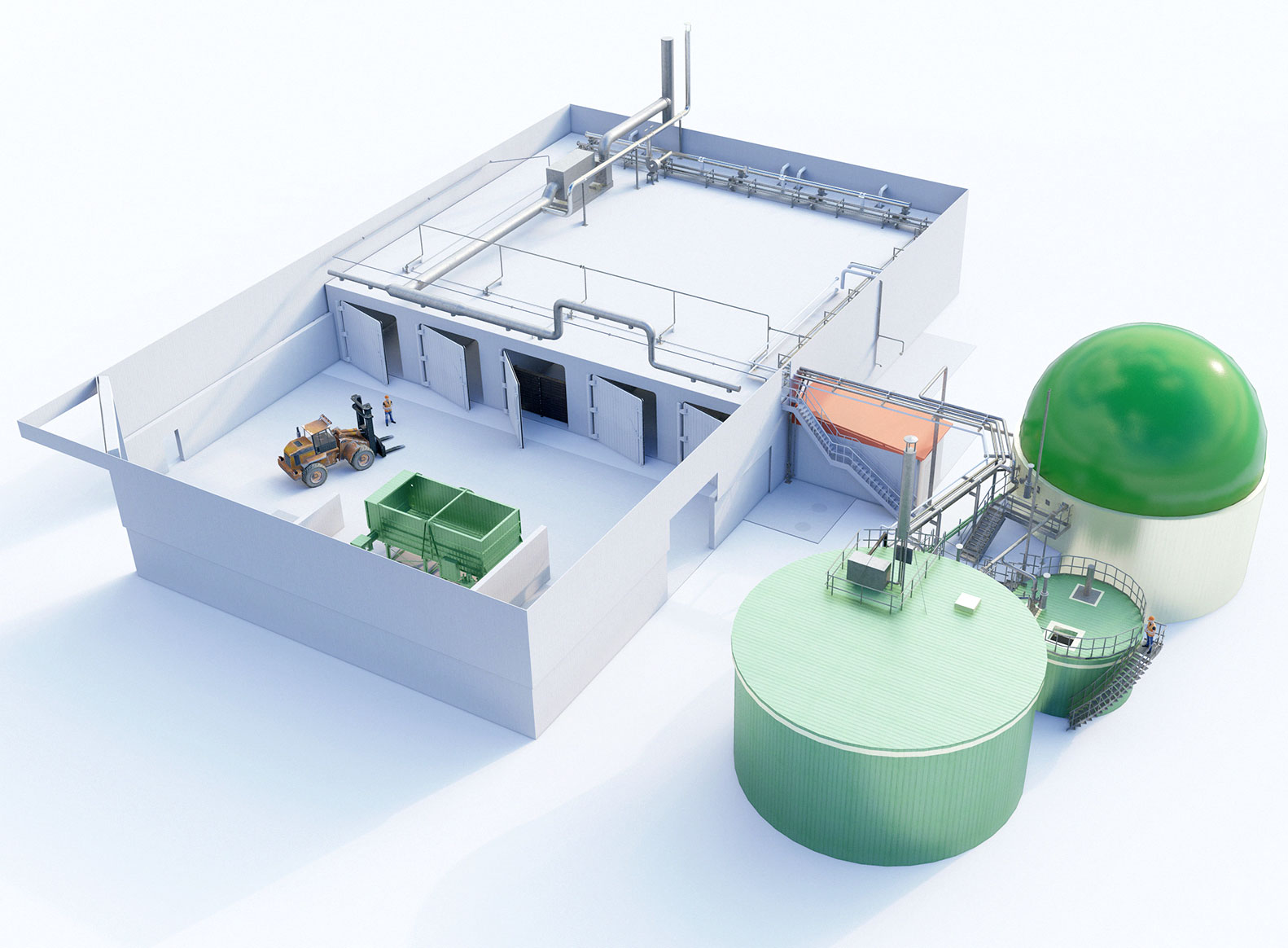

For farmers and disposers

RSD-S Compact Biogas Plant

The RSD-S compact biogas plant excels in solid matter fermentation, delivering efficiency and economic value within a minimal footprint. This compact system signifies decentralized energy production from a diverse spectrum of stackable substrates, including solid manure, straw, biowaste, green residue, landscape maintenance materials, and remnants of harvests and food.

“The sustainable use of resources is of great importance today. Biowaste and green waste from agriculture, the food industry, municipalities and waste disposal companies, in particular, are a raw material that is greatly underestimated. The correct utilization of these potentials leads to a profitable investment for operators, waste disposal companies and the environment”.

ANAEROBIC DIGESTION –

THE STATE OF THE ART

Our RSD biogas plant provides established technology for high solids anaerobic digestion, offering a viable solution for utilizing organic waste and residual materials rich in solid matter across municipal, industrial, and agricultural applications.

We guarantee quality and maximum uptime – and therefore economic and ecological success for our customers worldwide.

CASE STUDY: DIGESTION OF HORSE MANURE & STRAW

In Lehrte, Germany, farmers Adrian Bartels and Jens Boedecker employ our high solids anaerobic digestion system (biogas plant) to utilize horse manure effectively. Their team illustrates the economic success and ecological sustainability of this application with their innovative “problem solver”.

The horse, a cherished partner in hobby and leisure, is integral to our society. A single horse can produce up to 20 kg of manure daily. Considering there are approximately 1.2 million horses in Germany alone, the resultant manure volume is staggering. The animal’s waste has emerged as an economic element. The biogas plant, spotlighted for its energetic use of residuals, produces biogas through fermenting stackable manure and organic waste, which is then converted into electricity and heat via combustion in a combined heat and power plant. Horse manure, particularly from larger operations where it’s generated in sizable quantities and isn’t ideally processed in conventional liquid digesters/biogas plants, incurs disposal costs.

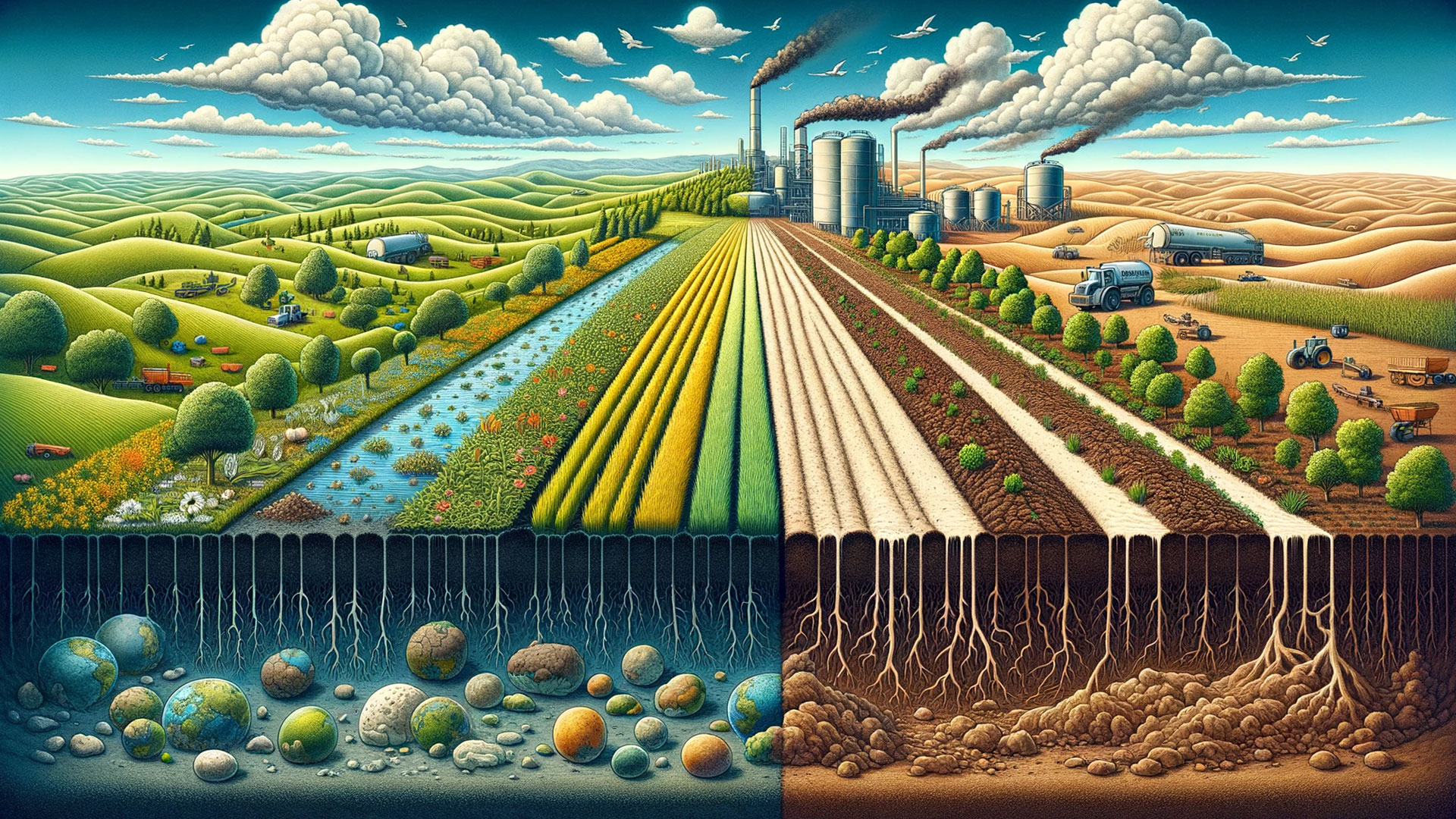

Beyond energy production and employing nutrient-dense organic fertilizer, enhancing the humus content in the soil has provided a considerable advantage over adjacent agricultural areas.

Given that there are around 1.2 million horses in Germany, over ten times the amount of horse manure is produced annually. This immense potential remains largely untapped, as detailed in our most recent Press Release

NEWS & TOPICS