ANAEROBIC DIGESTION & RESOURCE RECOVERY

Where traditional liquid biogas plants and plug flow designs end, our RSD® technology picks up. Dry fermentation uniquely empowers the processing of dry and fibrous materials (with a dry matter content of 20%-55%), which commonly challenge other systems.

Embracing a batch mode process, our system assures a steadfast biogas yield. The setup comprises multiple digester boxes (garage digesters), operating in a fixed fill-and-empty cycle. Minimal manual intervention is needed, as aside from elementary loading and unloading tasks, substrate pre-treatment (like shredding) is seldom required. Moreover, the substrate remains unmoved during the entire retention period (18-21 days), reducing technology failure and maintenance costs by forgoing sensitive stirring and pumping mechanisms (preventing floating and swelling layers).

A standout benefit of dry fermentation is its minimal substrate requirements. Substrates can contain impurities, which remain as residues post-process and have less dependency on particle size and fiber content. Picture domestic biowaste, often inclusive of residual materials like packaging, or horse manure with horseshoes or holsters, which can severely damage stirrers.

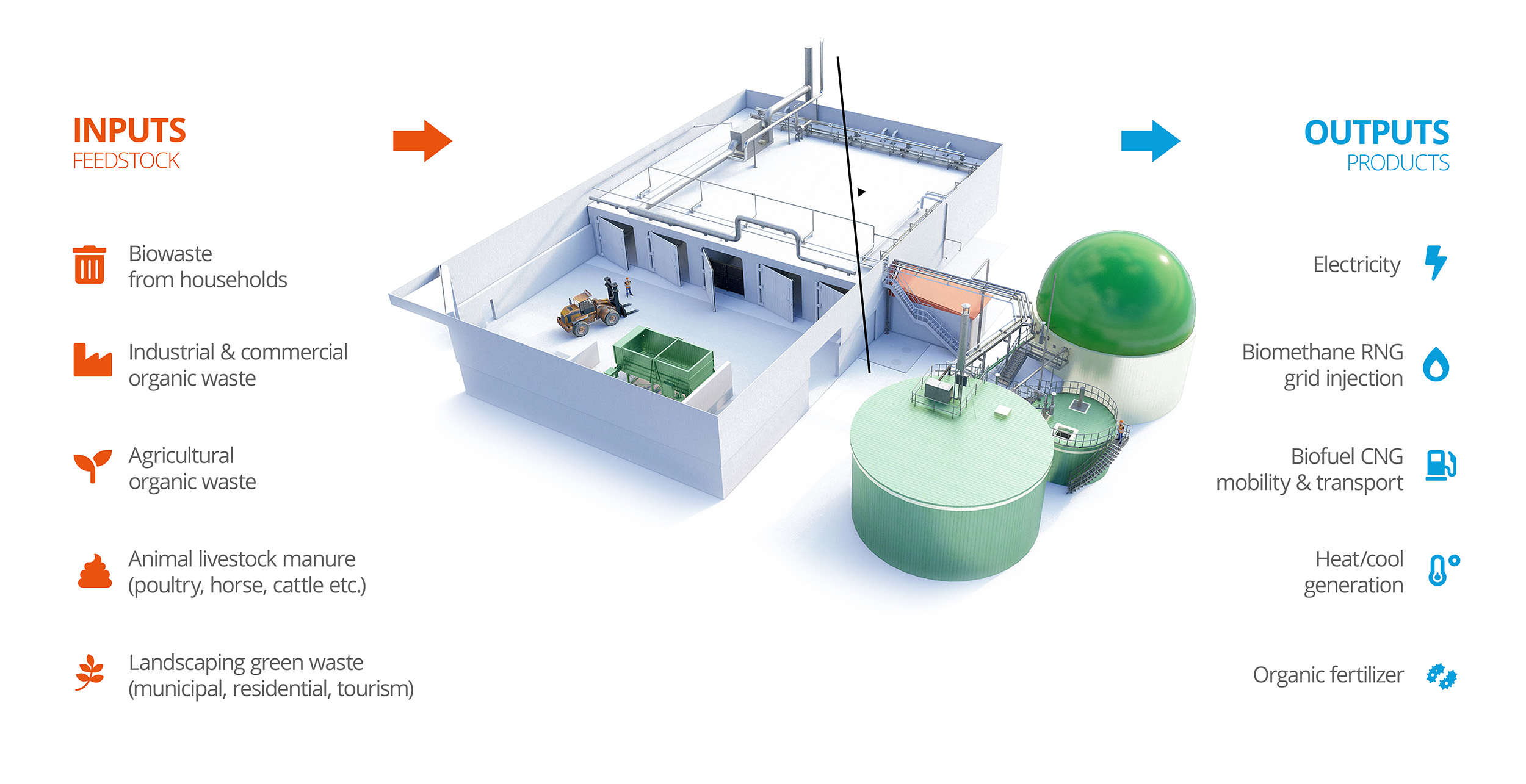

The generated biogas can be directly converted into electricity or refined into biomethane or bio natural gas, subsequently being integrated into the gas grid or utilized as vehicle fuel (CNG).

APPROPRIATE WASTE TYPES

Globally, the potential of organic waste is often undervalued both economically and ecologically. RENERGON turns this extensive range of material into value, providing our clients with both economic and technical advantages. Relevant substrates include:

BIOWASTE

GREEN WASTE

MSW (household waste)

AGRICULTURE WASTE

ANIMAL HUSBANDRY WASTE

SLAUGHTER BY-PRODUCTS

INNOVATIVE BIOGAS TECHNOLOGY

Transforming organic matter into biogas leverages a natural process, and aligning industrial methods closely with these inherent processes often yields superior results. Contrarily, technical systems that resist natural processes tend to amplify complexity, leading to heightened wear and operational failures. Consequently, RENERGON adopts a strategy of utilizing minimal, yet potent key components to bolster and amplify these natural processes. The outcomes are measurable synergistic effects: consistent biogas production, reduced wear, minimized energy consumption, and consequently, lowered life cycle costs, paired with an elongated plant service life and availability.

In utilizing Solid Anaerobic Digestion as the cornerstone technology (underpinned by the patented RSD® process – Renergon Simultaneous Digestion), the percolate, or process liquid, is recirculated, initiating and preserving the conversion of stackable biomass in the fermenter boxes into biogas. This cyclic percolate process ensures the homogeneous distribution of pivotal microorganisms, moisture, heat, and essential nutrients throughout the biomass. Additionally, the percolate, fortified with buffering substances, anchors the stability of the entire biogas process. Owing to the robustness of the plant technology and stable anaerobic (absence of oxygen) breakdown, impurities and foreign materials have a minimized impact.

FROM WASTE TO VALUE

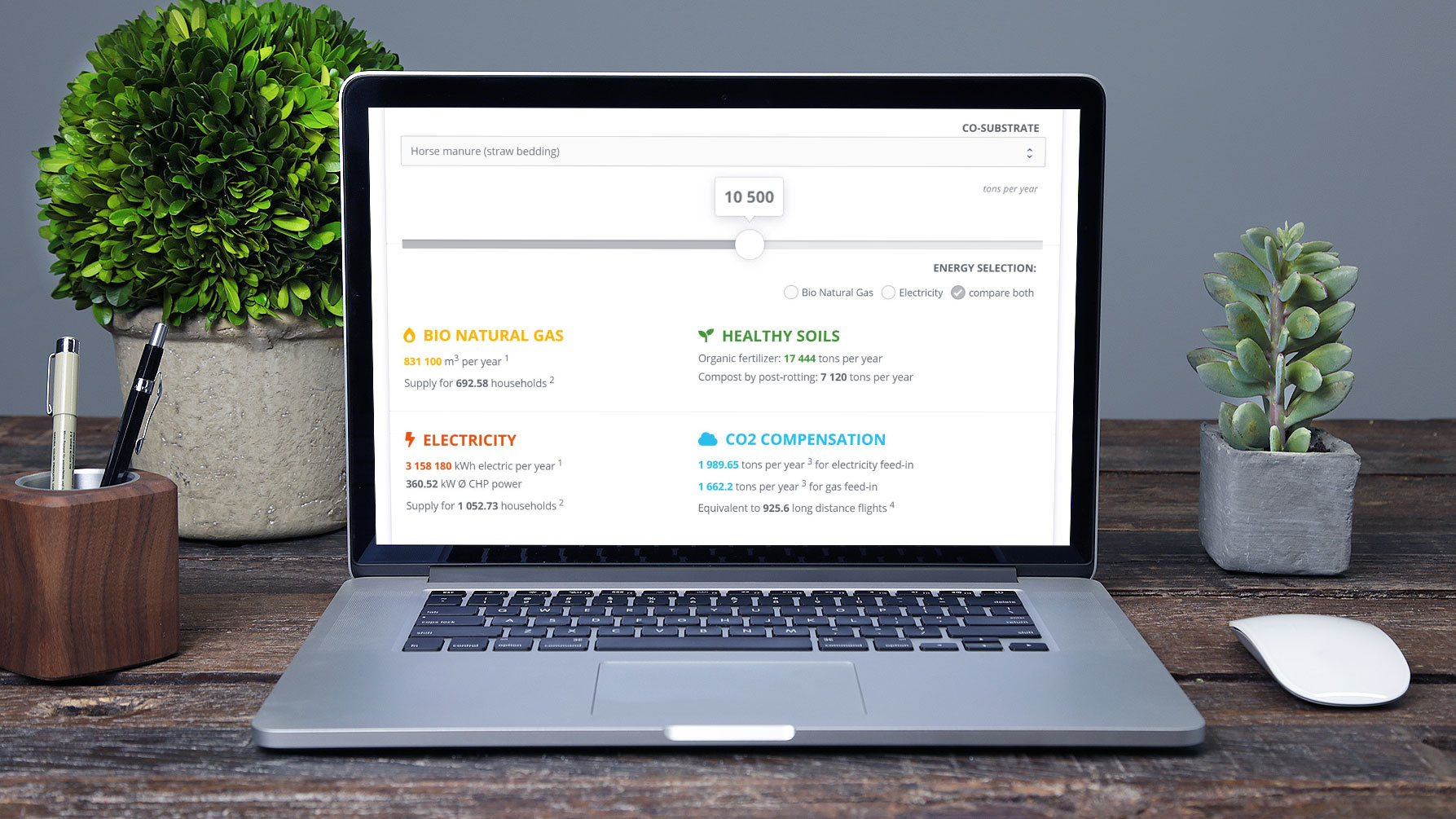

Our attention is centered on our clients. Your choice promotes a lucrative investment through the creation of renewable energy, fuel, compost, fertilizer, and biochar, as well as through the revenues from waste disposal and procured CO2 offset certificates.

Biogas stands as a multifaceted energy vector, possessive of the capabilities for transportation and storage. Beyond the generation of electricity and heat via a Combined Heat and Power unit (CHP), it can also be refined into bio-methane (bio natural gas). Subsequently, it can be integrated into the natural gas grid, utilized as fuel (CNG) for vehicles such as cars, trucks, and buses, or canistered and marketed to industries/commercial entities or private residences.

NEWS & TOPICS