This article will focus on a comparison and advantages of wet anaerobic digestion, plug-flow and dry digestion. An overview of commonly used biogas digester technologies for anaerobic digestion.

Source: Wikipedia

| technology | wet fermentation | plug-flow fermentation | dry fermentation (SSAD) |

|---|---|---|---|

| water requirement | |||

| range of substrates | |||

| tolerance to impurities | |||

| tolerance to inhibitors | |||

| risk of process failure | |||

| odor emissions | |||

| energy consumption | |||

| maintenance/wear | |||

| automated process |

| adverse | average | favorable |

Anaerobic Digestion Systems: What’s best for you?

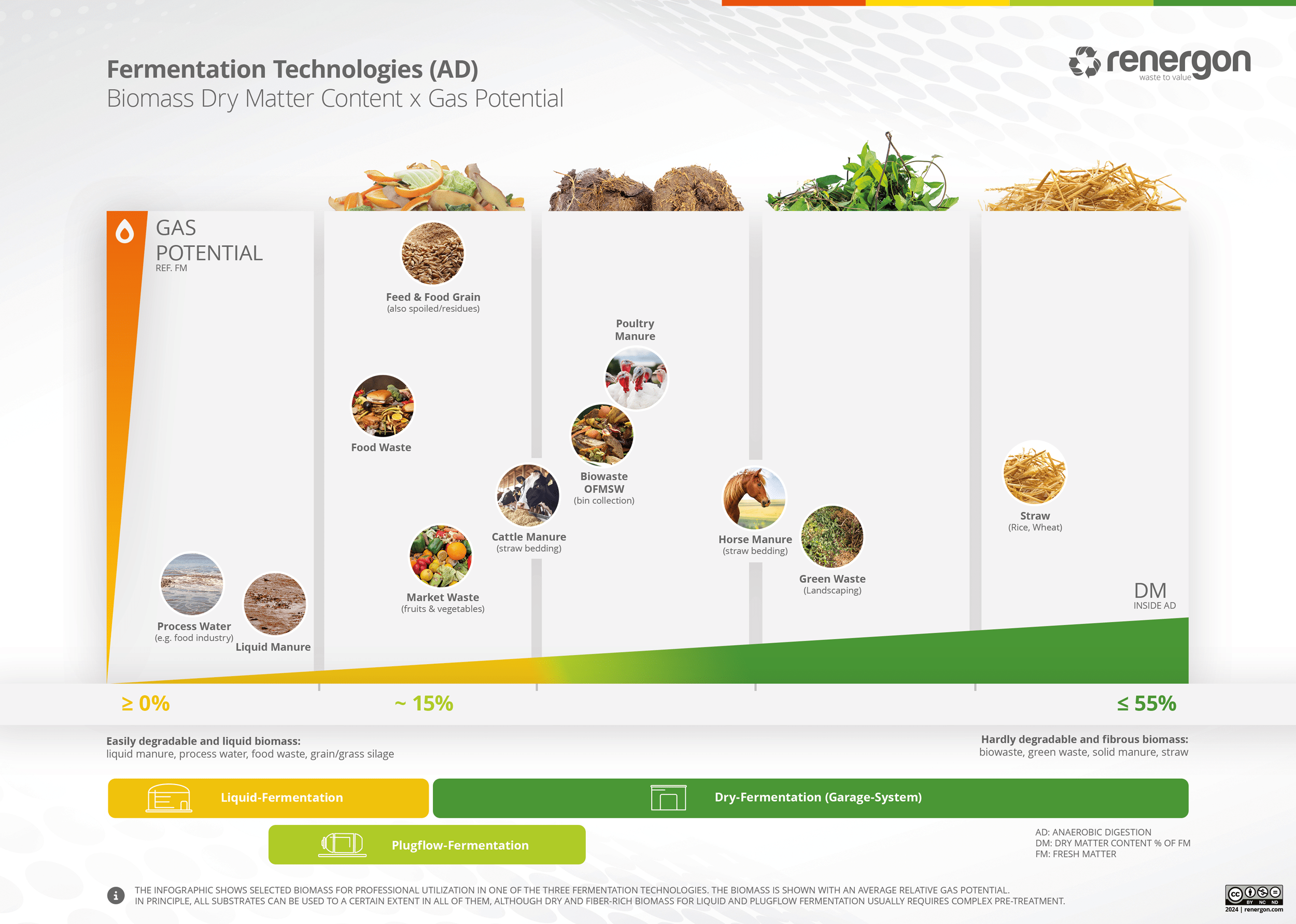

Most of the biogas plants worldwide are built based on liquid-type anaerobic digestion (AD), wherein biomass (usually animal dung) and water are mixed in equal amounts to form a slurry in which the content of total solids is about 10-15% (TS – total solids, DM – dry matter). While this model is suitable for small-scale biogas plants, it becomes a challenge in large commercial plants where it necessitates the use of large quantities of water every day, often in water-scare areas.

Solid state anaerobic digestion (SSAD), dry fermentation, as opposed to the liquid digestion described above, dramatically reduces the need to dilute the biomass before using it for digestion. SSAD can handle dry, stackable biomass with a high percentage of solids (20-55% DM – dry matter). A SSAD plant consists of gas-tight chambers called fermenter boxes working in batch-mode that are periodically loaded and unloaded with solid biomass. Liquid digestate or percolate produced during digestion is recirculated and sprinkled on the dry biomass to ensure process continuity and stability.

The solid state fermentation/dry anaerobic digestion distinguishes itself by the usability of a wide range of organic input substrates, including very dry or long-fibred ones that can be digested. Contaminants or impurities within the material will not affect the process of anaerobic digestion or the plant operation. Even energy rich liquid substrates can be integrated in the process without any problems. The uncomplicated close to nature technology ensures a quick and stable degradation process.

The operation of a dry/SSAD digestion plant, mostly automated. Only small maintenance work, beside charging and discharging the fermenter boxes after 18-21 days, has to be done manually. Whereas liquid digestion is often known as a 24/7 job, operating a dry digestion plant is a comparable lightweight job in terms of both time and effort. Just as time-consuming in liquid systems can be the pre-processing of the biomass to get it in the right particle size for feeding into the liquid digestion tanks.

Guide to Biogas Technologies: Choosing the Right

Wet Anaerobic Digestion

Wet anaerobic digestion is the most traditional form of AD technology, where biomass (typically animal dung) and water are mixed in equal proportions to create a slurry with a total solids content of 10-15%. This method is widely used in small-scale biogas plants due to its simplicity and effectiveness. However, the high water usage makes it less suitable for large-scale operations, especially in regions where water scarcity is a concern.

Advantages:

- Suitable for a wide range of liquid substrates.

- Proven technology with a broad base of operational knowledge.

Limitations:

- High water consumption.

- Increased risk of process failure due to dilution and potential imbalance.

Plug-Flow Digestion

Plug-flow digestion is a variant of the wet digestion process, designed to handle semi-solid biomasses with a higher solids content. In this system, the biomass moves through a “plug-flow” reactor, where microorganisms break down the organic matter. This technology is beneficial for farms and facilities with consistent waste characteristics.

Advantages:

- Efficient for semi-solid substrates.

- Lower water requirement compared to traditional wet digestion.

Limitations:

- Less flexibility in substrate variability.

- Moderate maintenance and monitoring requirements.

Dry Anaerobic Digestion (SSAD)

Solid-state anaerobic digestion (SSAD) or dry fermentation represents a significant advancement in AD technology, allowing for the processing of dry, stackable biomass with a solids content of 20-55%. This technology operates in batch mode within gas-tight chambers, reducing the need for water and offering a more sustainable solution for areas with limited water resources.

Advantages:

- Low water requirement.

- High tolerance to impurities and inhibitors, making it suitable for a wide range of substrates.

- Lower risk of process failure and odor emissions compared to wet systems.

Limitations:

- The initial setup and capital costs can be higher than those for liquid systems.

Conclusion

The choice of anaerobic digestion technology depends on various factors, including the type and availability of biomass, water availability, investment capacity, and operational preferences. While wet anaerobic digestion remains a viable option for small-scale applications, the plug-flow system offers a middle ground for those dealing with semi-solid wastes. On the other hand, dry anaerobic digestion (SSAD) stands out as the most advanced and environmentally friendly option, particularly for large-scale operations looking to minimize water use and maximize flexibility in substrate choice.

In summary, as the demand for renewable energy sources and sustainable waste management practices grows, understanding the nuances of each biogas technology becomes essential. By carefully considering the advantages and limitations of wet, plug-flow, and dry digestion technologies, stakeholders can make informed decisions that align with their operational needs and environmental goals, paving the way for a greener, more sustainable future.