Black and inconspicuous from the outside. The huge surface area and porous structures make plant carbon, unique and so valuable for many areas and use. Vegetable carbon is biochar from a purely vegetable source – produced from vegetable biomass that accumulates in agriculture, horticulture, and landscaping, as well as municipal collections. For example, it is carbonized from straw, green waste, solid manure, slurry, or sewage sludge at high temperatures and in the absence of oxygen. This process is called pyrolysis or thermolysis.

The history of charcoal (= biochar) begins 2,800-4,000 years ago (Iron Age) with its production for iron smelting, i.e. vegetable charcoal is biochar from a purely vegetable source.

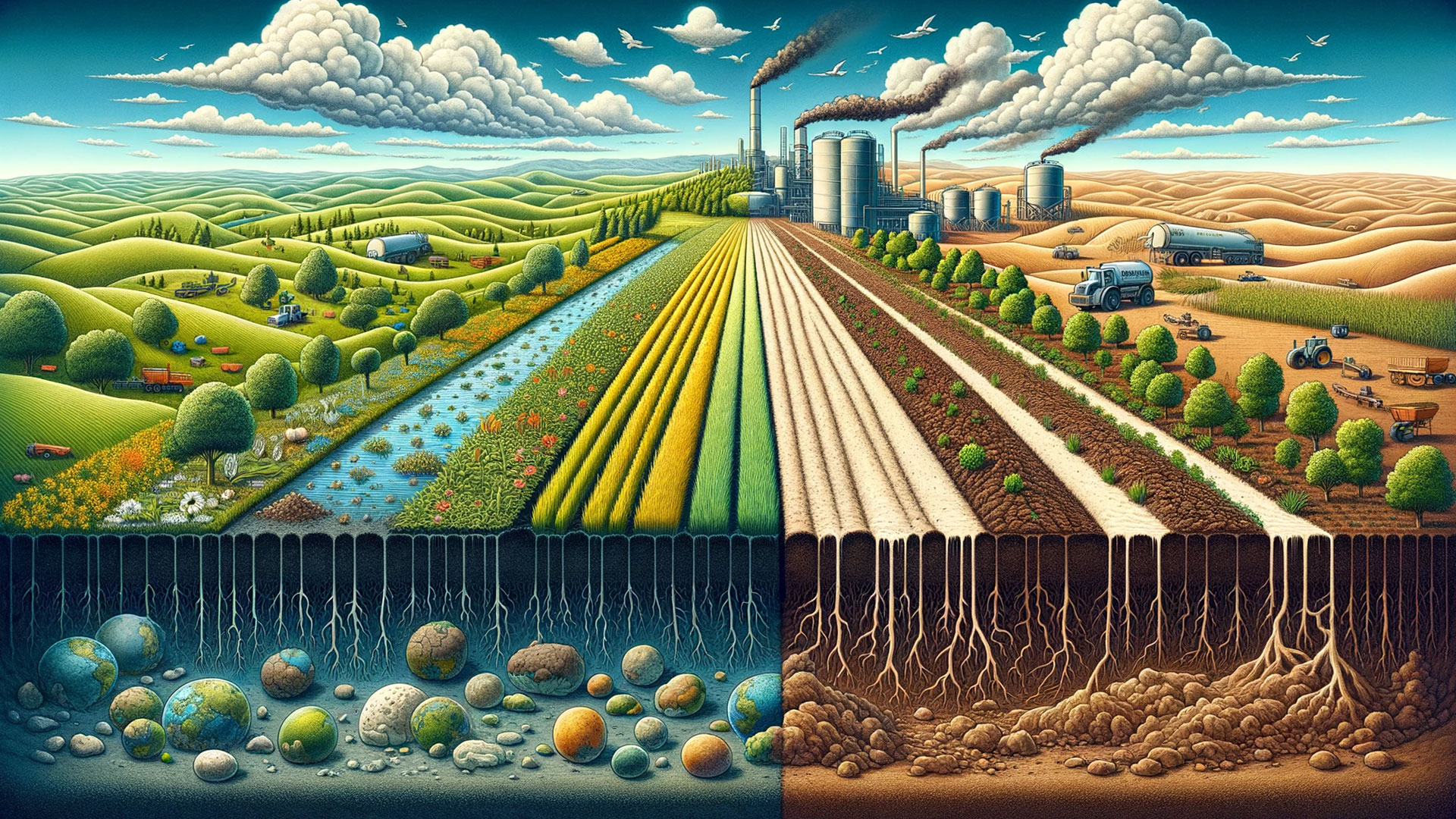

Biochar can be produced not only from wood (vegetable carbon), but also from any biomass, such as straw, green waste, solid manure, slurry, sewage sludge, or fermentation residues. Moreover, unlike charcoal, the use of the term plant charcoal does not primarily focus on energy recovery, but rather on incorporation into agricultural soil to store carbon dioxide in the long term and improve soil quality.

The production of biochar from biomass takes place under the influence of heat and with reduced availability of oxygen. Several processes are available for this, which differ in process speed, maximum temperature, process duration, and product yields.

The most common methods are:

- Pyrolysis (400-800 °C)

- Hydrothermal carbonization (HTC)

- Thermolysis

Hydrothermal carbonization takes place in an aqueous environment under pressures of approx. 20 bar and temperatures of 180-250 °C, which means that it is also possible to use wetter starting material. The processes for the production of HTC coal are by far not yet as mature as those for pyrolysis coal, also with regard to the coal qualities.

Thermolysis is a chemical reaction in which a starting material is decomposed into various products by heating. In contrast to thermal decomposition (= pyrolysis), thermolysis is used specifically to produce defined products or reactive intermediates. It breaks down the organic materials into thermolysis gas and a solid residue (thermolysis coke).

In contrast, the term “cracking” is used when medium- and long-chain hydrocarbons (heavy fuel oil) are split into short-chain hydrocarbons (gasoline, diesel, and light fuel oil) during petroleum processing.

Among other things, biochar is seen as having great potential as a means of offsetting carbon dioxide emissions in the face of global warming – Negative Emission Technology (NET). See also: “CO₂ compensation using biochar”.

More on the topic around biochar and biogas can be found here: “How does a biogas plant work?” and Wikipedia.