| Location: | Langenau, Germany |

|---|---|

| Biomass: | Green waste, crop residue |

| Quantity: | 15.000 t/a |

| Biogas: | 1.800.000 Nm3/a |

| Performance: | 430 kW el. Ø |

BIOGAS PLANT & COMPOSTING SITE

Langenau, Germany

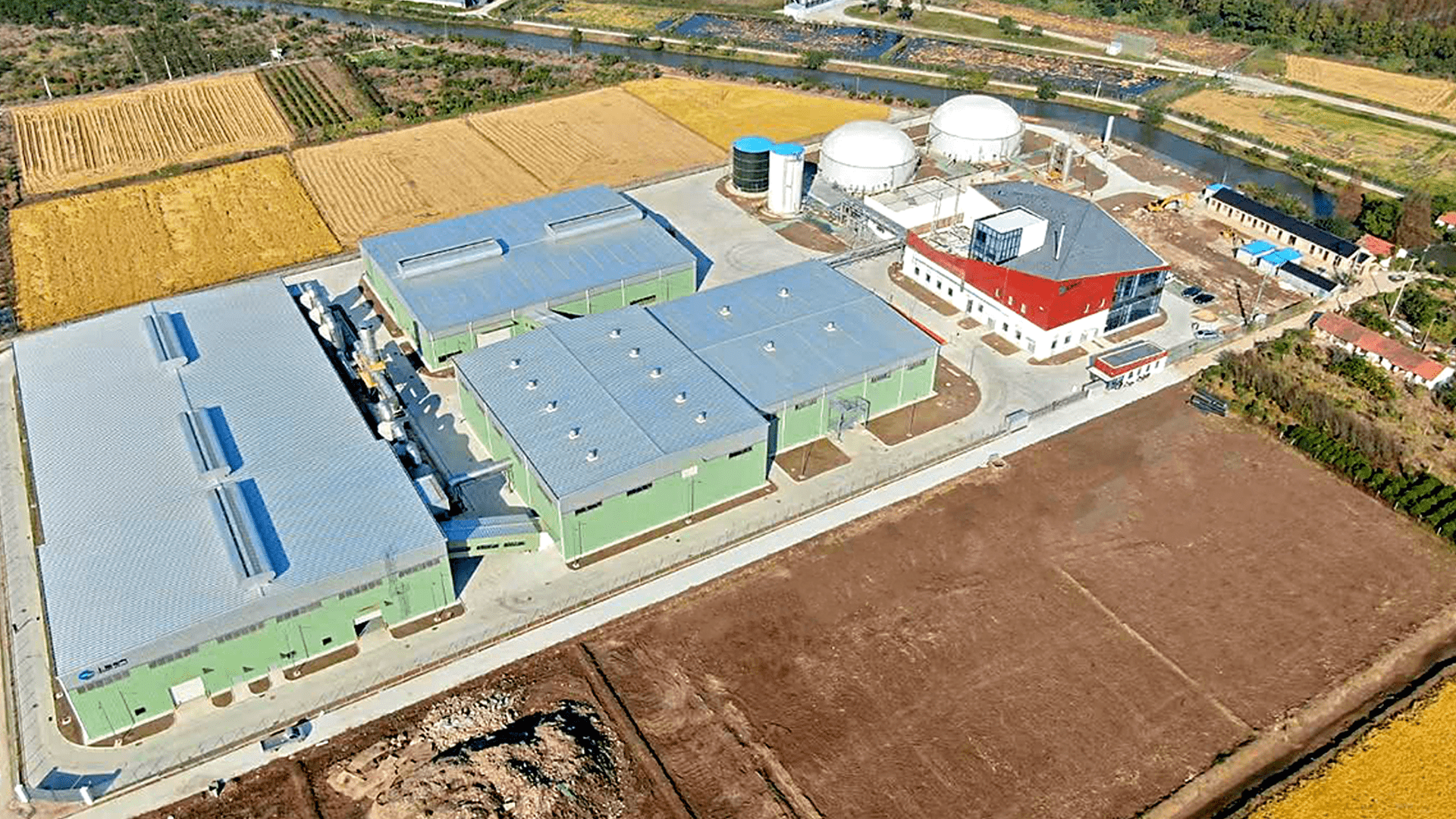

The Langenau biomass facility in Germany is an outstanding example of the innovative utilization of biomass. By integrating a solid matter fermentation plant into an existing municipal green waste composting plant, the biomass farm has optimally expanded its functions. This combination of composting and biogas production offers an efficient way of operating in an ecologically and economically sustainable manner.

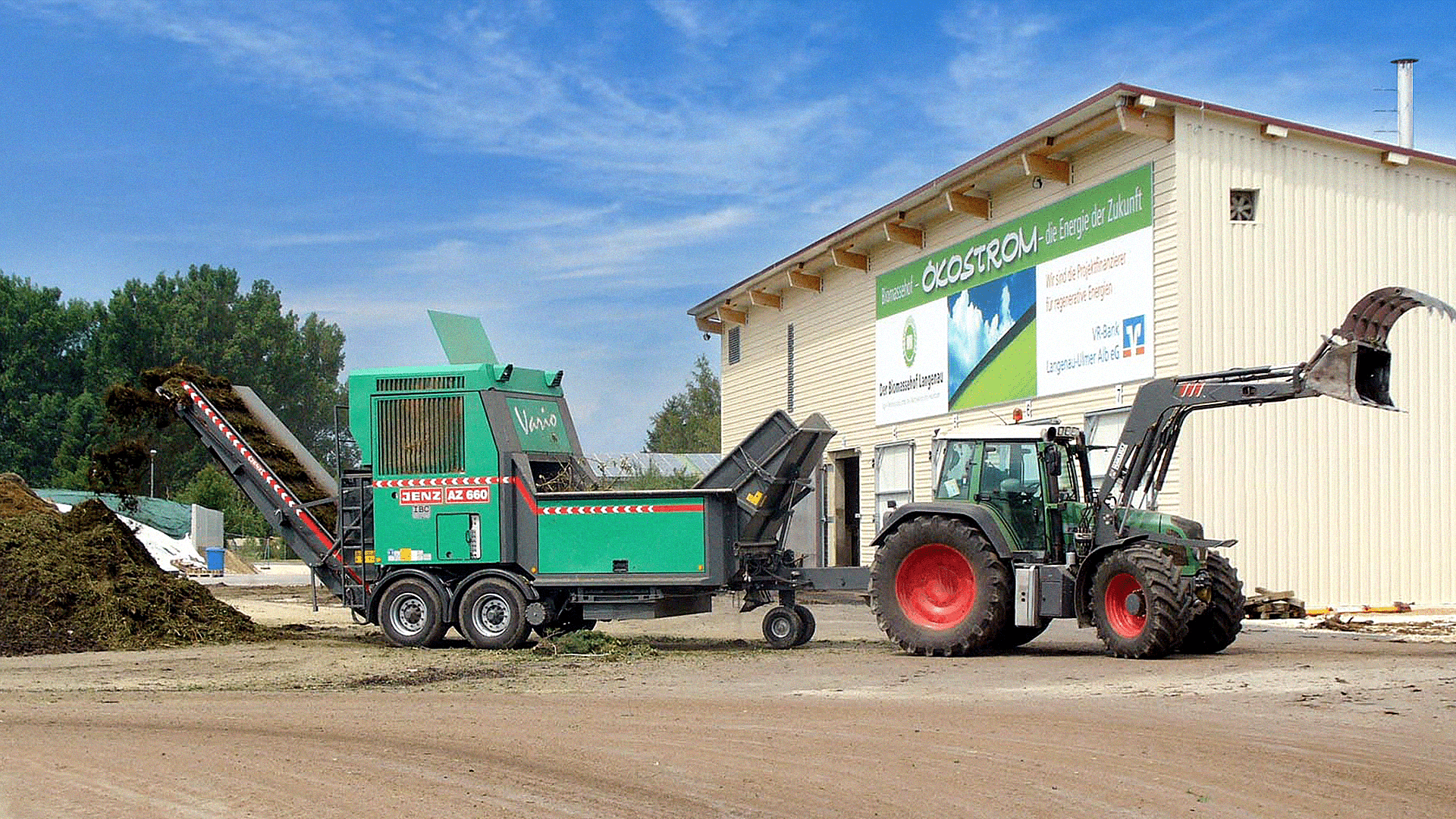

Efficient collection and processing of green waste

The “Biomassehof Langenau” focuses on the collection and fermentation of municipal, commercial, and private green waste. This includes the acceptance of green waste, consisting of woody plants, grass and hedge cuttings, as well as the production of high-quality compost with a seal of approval. It also sells compost, potting soil, bark mulch, wood chips and roof garden substrates, covering a wide range of services.

The eco-balance of the biomass farm is impressive: The plant supplies around 1,000 households with electricity, and the heat generated is roughly equivalent to the energy content of 400,000 liters of heating oil. These impressive figures illustrate the biomass farm’s contribution to a sustainable energy supply.

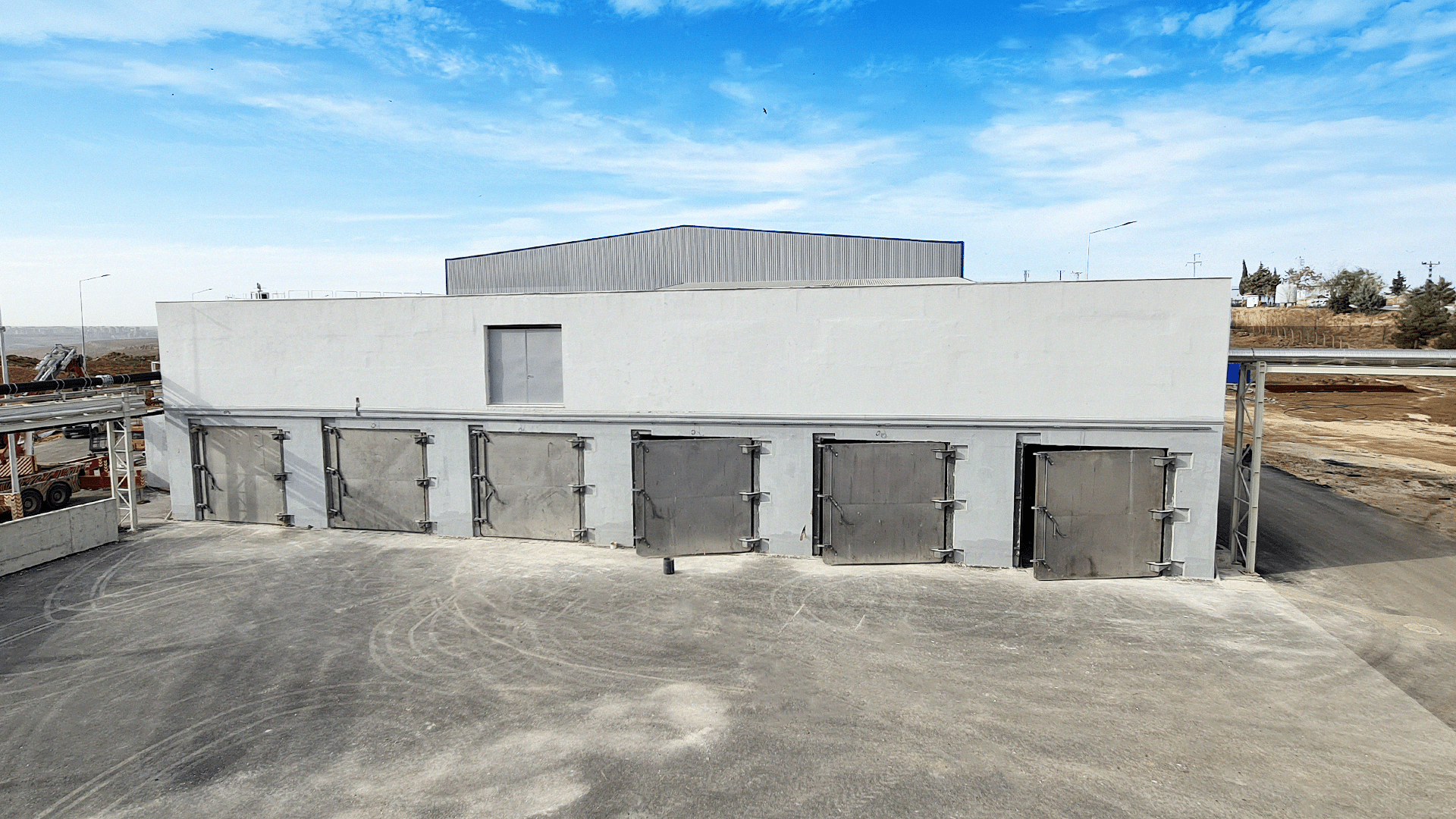

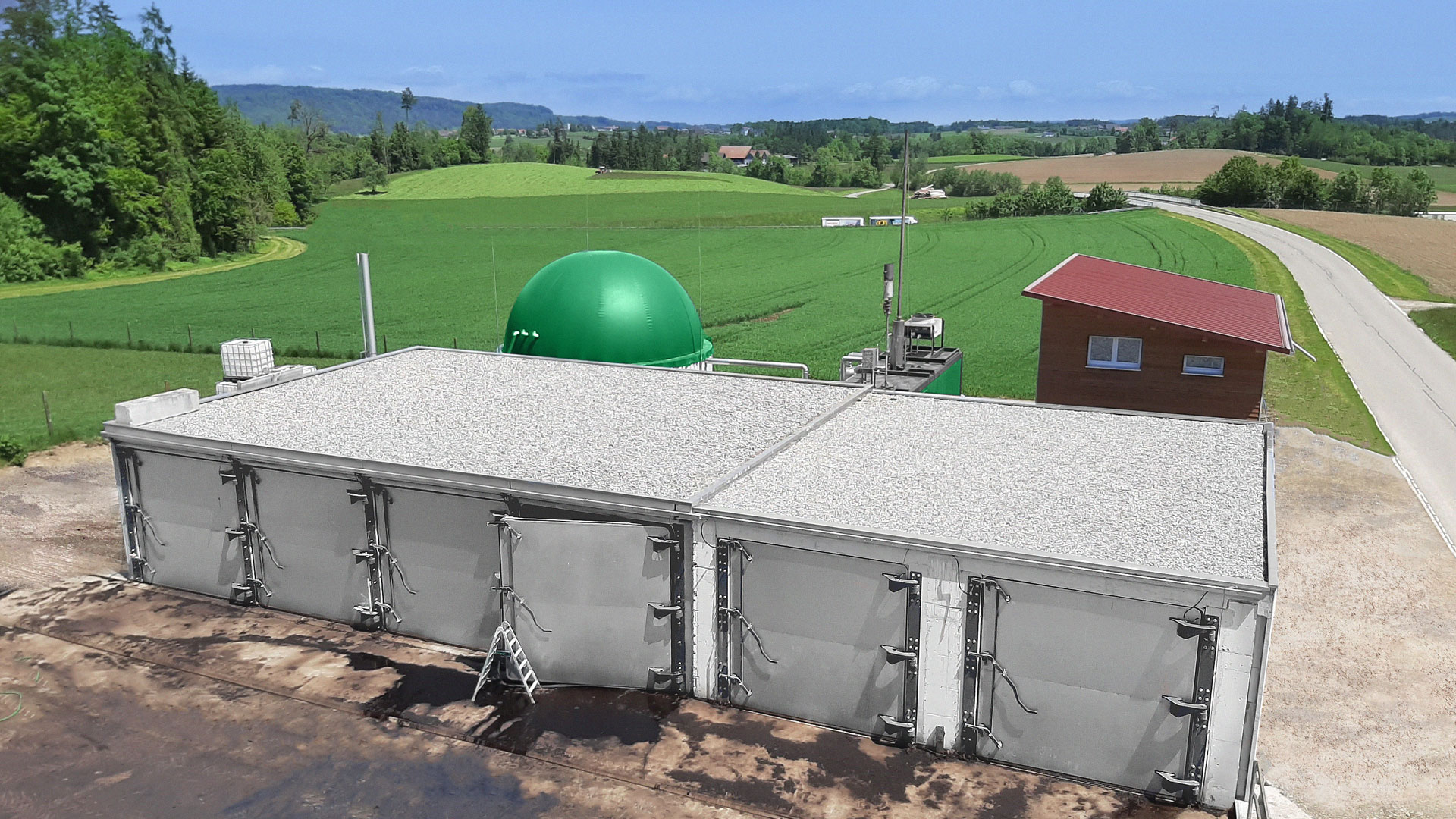

Innovative technology using dry fermentation

Solid matter digestion forms the heart of the plant. This type of fermentation is characterized by batch operation, in which the material flow is discontinuous, but biogas production is continuous. The fermenters, which are constructed like garages, are filled at different times and operated by means of percolation. A special feature of this technology is that the dry substance of the feedstock is over 30% and the plant’s own power requirement is very low due to the absence of agitators in the digester. In addition, it is highly resistant to impurities and can be used with a wide range of materials.

The fermentation process includes the rough mixing of the fermentation substrates and their filling into the fermenters. After the fermenters have been sealed gas-tight, they are sprinkled with percolate at intervals. After around 21–30 days, gas formation is largely complete. The fermentation residue is then removed and either used as fertilizer or further used for composting.

Comprehensive energy use

The plant produces around 1,800,000 Nm³ of biogas per year with a methane content of 53%. The average power generation is around 430 kWel. In addition to electricity production, the thermal energy is also used to supply a public swimming pool. In addition, the biomass farm provides compost and fertilizer for agricultural land, creating a closed cycle from waste disposal to energy and fertilizer production.

Overall, the Langenau biomass facility demonstrates how the combination of traditional composting and modern biogas technology can create an efficient and environmentally friendly energy management system that contributes to both the local electricity and heat supply and makes an important contribution to sustainability.