How sustainable is an anaerobic digestion biogas plant? The increasing substitution of fossil fuels, such as natural gas, by biogas, would dramatically improve the climate balance. In principle, there would be no shortage of climate-neutral biomethane. Biomass is probably the most underestimated natural and never-ending resource in the world.

Waste incineration and landfill are representative of the globally prevailing linear economic system and contradict the principle of sustainability.

The circular economy takes nature’s material cycle as its model and attempts to achieve cascading uses without waste and without emissions. In our world with finite resources, only the recycling economy is sustainable.

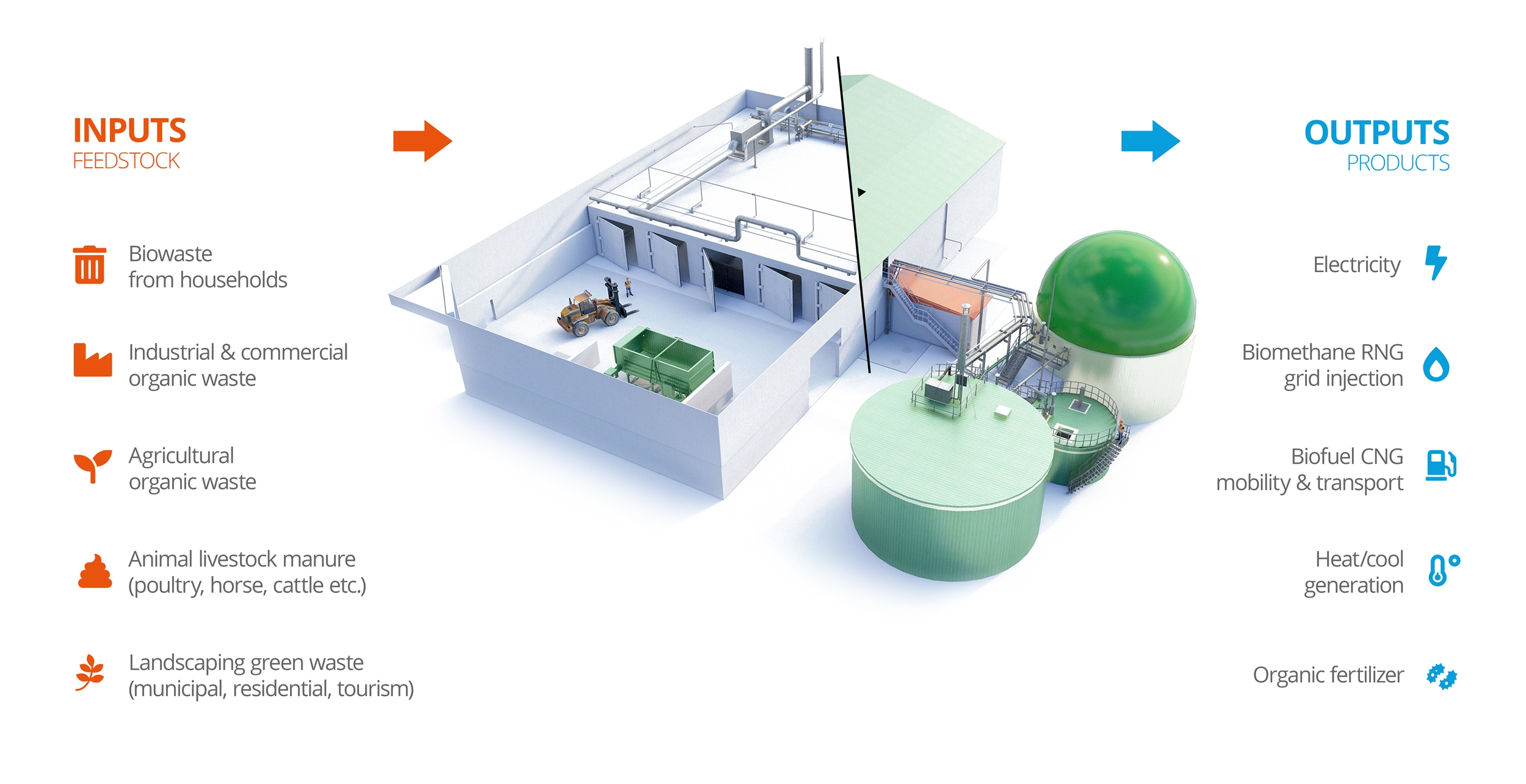

Today’s raw material sources are green in the sense that they are renewable and carbon-neutral. Organic residues and waste, from municipal collection (organic waste, green waste), from animal husbandry and breeding, as well as agriculture and arable farming, from the food industry and gastronomy, become clean, renewable energy, valuable organic fertilizer and compost for healthy soils – all in the spirit of a sustainable cycle.

Biowaste – An Unused Potential Worldwide

In addition, biogas is permanently available, transportable, and storable regardless of weather or season, and can, therefore, be used flexibly — for example, for local or regional energy supply and as an energy source in the mobility sector. In its production, it is emission-neutral and avoids climate-damaging methane emissions from landfills. Methane is 25 times more potent than the greenhouse gas CO2, which is considered the main driver of global warming.

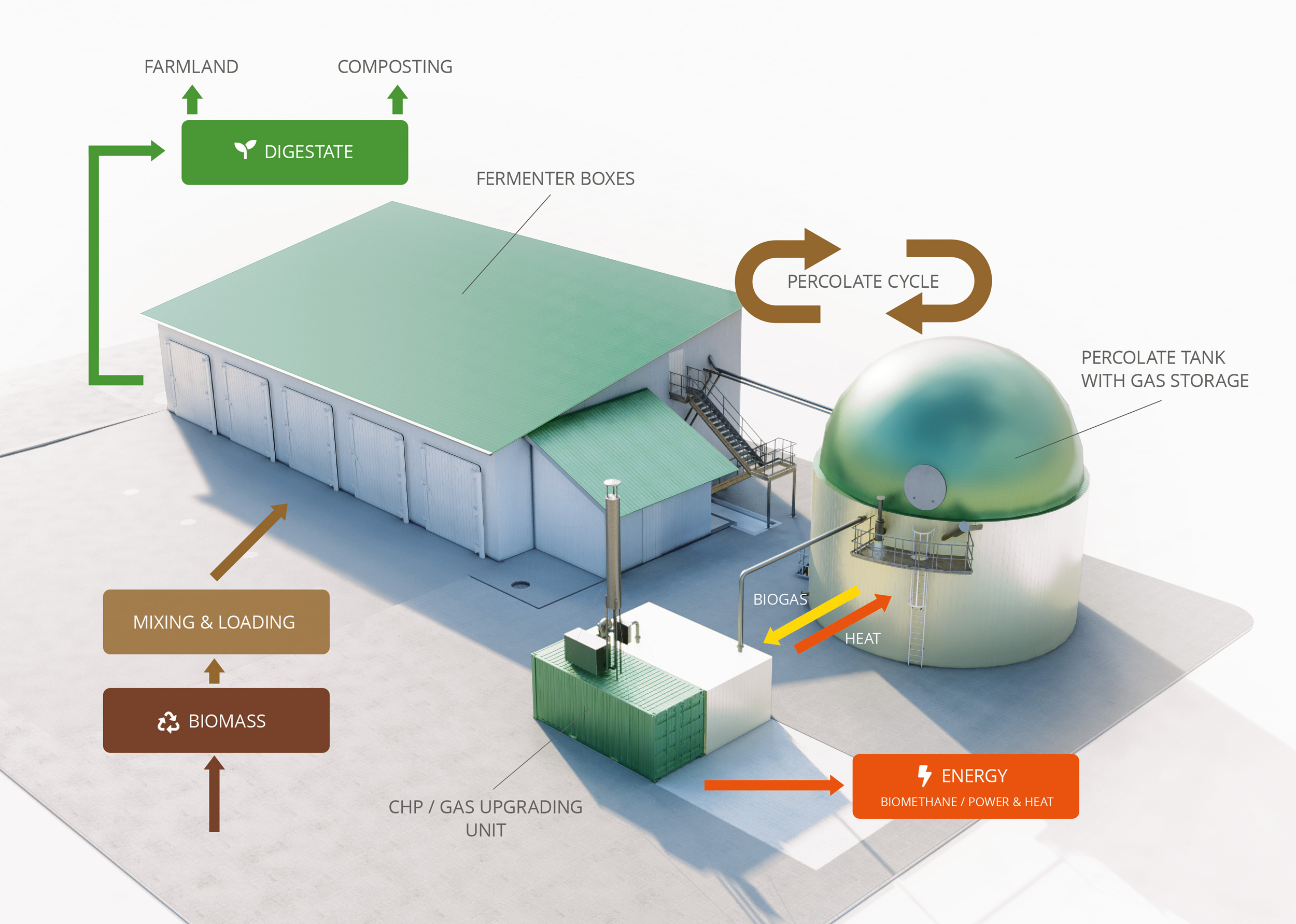

Dry fermentation or solid fermentation (SSAD) has proven to be the optimal technology for the utilization of these organic residues and wastes, which are predominantly available worldwide in a solid and stable form. This is regarded as the new generation of technology for a biogas plant (AD plant).

- Substrate flexible and specially designed for biomass with high solid and dry content

- Absolutely insensitive to impurities and contaminants (e.g., plastic, metal, stones)

- Robust, simple technology with low maintenance and downtimes

Further Advantages of Dry Digestion:

- Low labor and operating costs

- No, or little mechanical pre-treatment of the biomass necessary

- Low maintenance and wear and tear on plant components

- Low water consumption and therefore suitable for dry, arid regions around the world

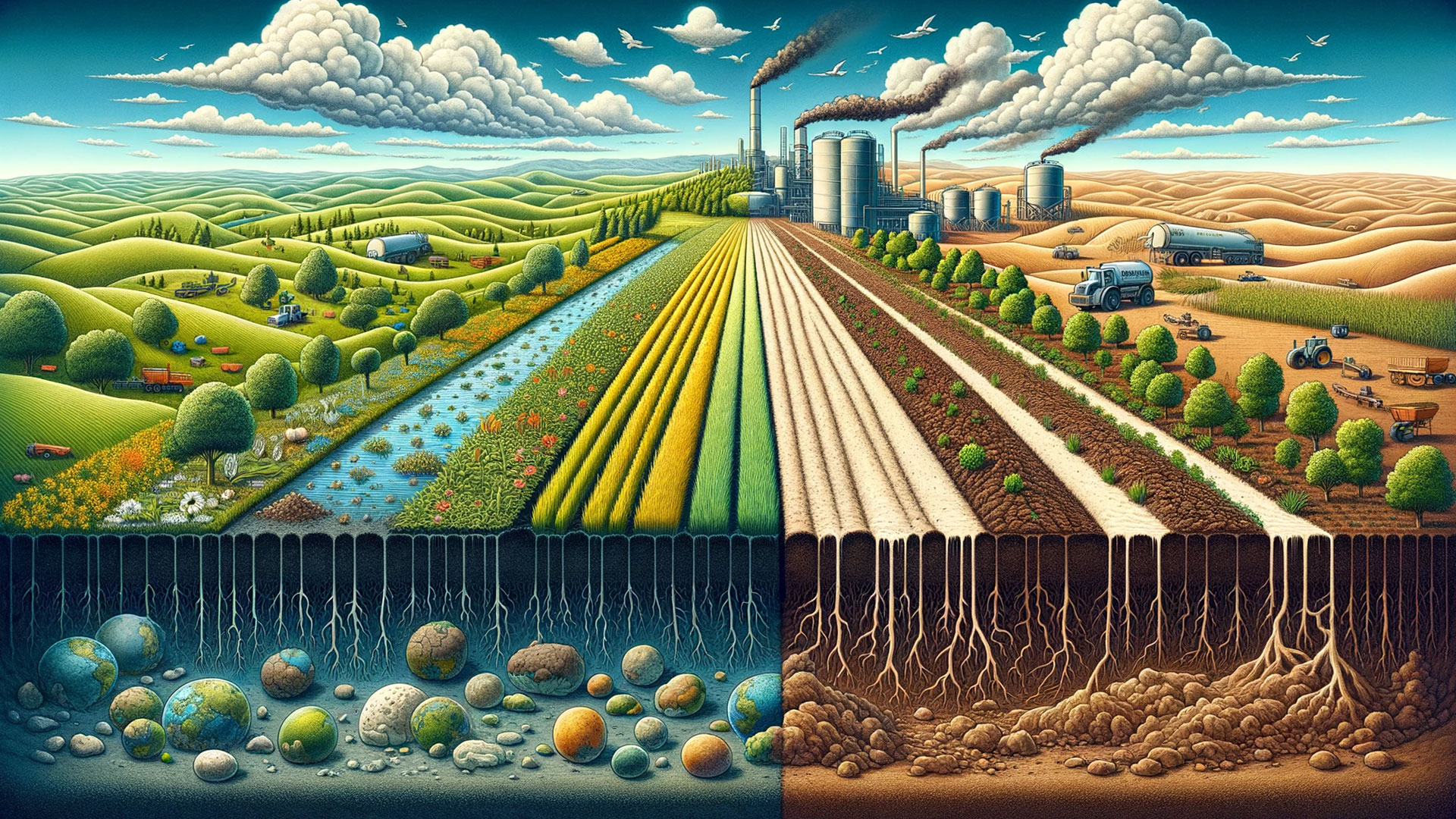

The cycle closes when the organic residue, the digestate, is returned to the soil with the nutrients it contains as a potent fertilizer with high humus content after fermentation.

In addition to the fertilizing effect of nutrients available to plants, the practical application shows an improvement in soil structure, including a steady increase in the proportion of hummus on arable land. This humus structure drastically improves the water storage capacity of the soil. Therefore, more than 70% of crop failures are avoidable in dry periods.

Particularly in very dry regions of the world, some with water shortages, this fermenting material provides a basis to transform parched, desert-like areas back into green and fertile growing areas and to counteract further desertification.

Biogas Digester Plant for Sustainability

Our lighthouse project in Sundern, Germany, is a prime example of sustainability and closed cycles with worldwide impact.

At the Hellefelder Höhe composting plant, 20,000 tonnes of biowaste from surrounding communities are recycled annually. And all this in the sense of the German Recycling Management Act, which stipulates that first the energetic and then the material recycling must be carried out (cascade use).

The biogas produced in a biogas plant (AD plant) from the biowaste is used for flexible electricity production by two combined heat and power plants, which also generate about twice as much heat. Thus, about 1200 households can be supplied with electrical energy. The heat produced is used by the fermentation plant to maintain the thermophilic process temperature of 52 °C and to heat adjacent building installations.

As quality compost and soil are the desired end products in the composting plant, the delivered biowaste and green waste from the municipalities is first freed from coarse impurities. A wheel loader stacks the biowaste in the next free fermenter box of the biogas plant up to a height of about 2.5 m. The fermenter box is closed gas tight by a gate with an inflatable seal. The organic material is not moved during the entire residence time of 21 days. Therefore, the solid matter fermentation does not require complex and susceptible pumping and stirring technology.

One to two fermenter changes, consisting of emptying and refilling, are carried out per week (batch process). The number and size of the boxes determined in the plant layout are so designed to handle the available material in the most efficient and economical manner possible.

In addition to turnkey plants in the DACH region, RENERGON, headquartered in Switzerland, offers the possibility to make this superior technology available worldwide through its international partner network of licensees.

The plant layout and design are determined in Switzerland. Construction is carried out with local resources and manpower under the supervision of local partners. The latter are instructed in theory and practice through a regular and intensive training program in our Swiss training center to ensure the high Renergon quality in all phases, from the start of construction to commissioning.

This enables safe and economical operation in any region of the world at environmentally friendly and social conditions.